The UFDS visited the good ship Mary Arctica in Nuuk on the same day as an inspection of one of the vessel's outer tanks took place and could therefore watch as Chief Mate Lars M. Bentzen made his way into – and back out of – the small compartment.

In connection with visiting DFDS, ForSea and Stena Line, UFDS has spoken and heard a lot about one of the tasks where safety is at the very top of the agenda, namely inspection of small hard-to-reach compartments – aka enclosed space – where even minor accidents can quickly become major issues.

When access to the work area takes place through a hatch the size of a medium-sized flat screen, it goes without saying that procedures, chains of command and patterns of action for handling accidents must be completely in place before the task begins.

This is also the case – we would soon discover – aboard the Mary Arctica, a medium sized feeder ship from Royal Arctic Line, which the UFDS visited in Nuuk, Greenland mid-March.

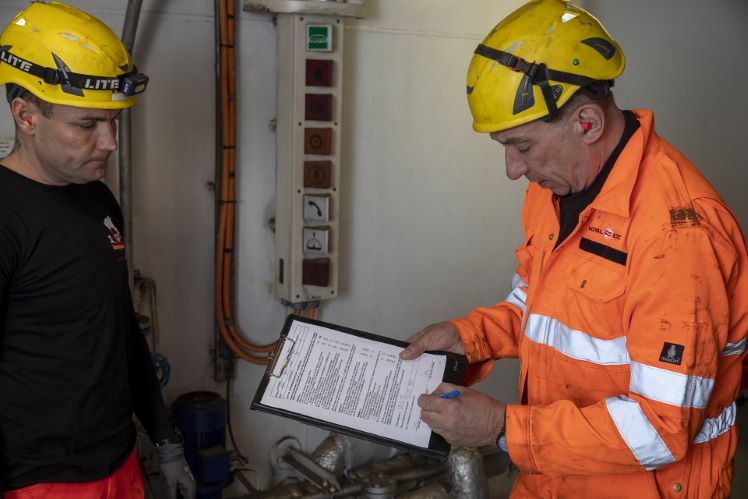

Upon boarding, we are greeted by Chief Mate Lars M. Bentzen, literally a checklist under his arm, as he is suiting up to make his way into one of the vessel's outer tanks, which is no small feat indeed.

Flanked by both 1st and 2nd mates on the ship, he dons an orange boiler suit and helmet, supplementing with an oxygen meter, powerful flashlight and radio. The oxygen meter can also detect vapors of, for example, methane from chemicals, and constantly monitors the airflow in the tank.

Everyone knows the playbook

This particular outer tank – a cofferdam or void space – are equipped with hatches on both port and starboard sides, ensuring reasonable ventilation and minimizing the risk of fumes. When dealing with (even) smaller compartments, ventilation is set up a few hours in advance before the inspection takes place, air flow kept at a constant level throughout the task.

»To begin with, I always look at the remarks from the last inspection; ‘Generally appearance is quite nice, some dirt at the bottom, no damages observed, both bilge alarms ok'. Then I can activate one of the alarms giving the guys in the control room a signal, and that's pretty much it,« Lars M. Bentzen says.

The fact that there are two men on the outside is far from coincidental. One is in direct contact with the colleague inside the tank during the task, another is on standby to be able to call for help if an accident should occur. In addition, the rest of the crew is informed that the task is in progress, so that they know what to do if assistance is needed.

Inside the tank, the experienced chief mate moves around carefully – the "floor" consists of transverse steel frames knee high above the bottom – to look for impressions from the hull side and take note of any serious damages.

Since the tank is not intended for liquids, it is equipped with the two aforementioned bilge alarms that can alert the ship's engineers should an unwelcome floating guest have entered.

In addition to outer tanks like this, Lars M. Bentzen and his colleagues regularly inspect the ship's ballast and oil tanks, taking pictures as documentation and sending these to RAL's fleet surveyor. Pending any new comments, a decision can be made whether anything needs further inspection the next time the ship is in dock.