With the launch of the methanol-powered container ship Laura Maersk, new, greener winds are blowing on the world's oceans. Although not without its challenges the new fuel is in some ways it is preferable to diesel or LNG, chief engineer states.

In mid-September 2023, the world was introduced to Laura Maersk at a ceremony in the port of Copenhagen, where the ship was officially named and christened by European Commission President Ursula von der Leyen, with the entire A.P. Moller – Maersk top management and the world press as witnesses.

»I'm not worried about sailing with methanol at all.«

Heino Søgaard Nielsen, chef engineer, Laura Maersk

The great attention paid to the 2,100 TEU capacity vessel, only allowing her take about a tenth of the amount of container for which the large Triple E ships are built, is to be found in the engine compartment and not least the fuel tanks, where new ingredients have been added to the recipe.

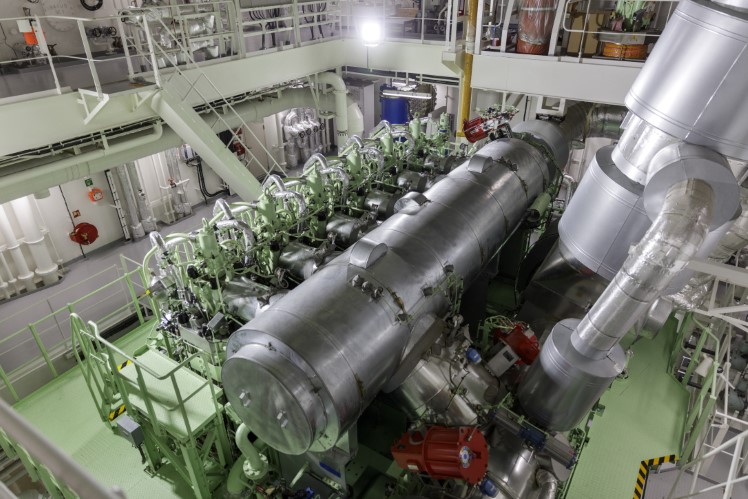

The main engine of the Laura Maersk, a Hyundai-MAN B&W 6G50ME-C9.6 capable of producing just over 10 MW, will be powered by methanol from two tanks with a total capacity of 1,400 m3. With them full, the vessel can cover up to 6,000 nautical miles between bunkering despite a somewhat lower energy density than in conventional MGO.

UFDS has visited Laura Mærsk in Halmstad, where the Danish shipping giant held another event to show off the vessel. According to Area Managing Director Nordics in Maersk, Birna Ödefors, the new ship represents 'a historic step in the right direction'.

»It is the first green methanol ship in the world, and it is very symbolic for us that we can launch it as the first. This is part of our net-zero target that we have set for 2040, where all our modes of transport must be serviced with net zero impact on the climate,« she says.

In addition to the climate related aspects of operating on methanol, there are also a string of new safety considerations associated with the move away from traditional propellants, which we discussed with one of Laura Mærsk's captains, Dutchman Pieter van Rijn, and not least the ship's Danish chief engineer, Heino Søgaard Nielsen.

It is Pieter van Rijn who greets our small group on board, and already a few meters from the gangway, the new reality becomes visible. Thus, a large area on deck is painted up in a strong purple, indicating the bunker zone of the vessel.

Methanol is toxic, he emphasizes, and therefore the zone is clearly marked, accompanied by a message that only relevant crew members are allowed to stay in the area during bunkering, always carrying gas detectors.

Initial fears are put to rest

In the control room, we meet Heino Søgaard Nielsen, visibly pride and eager to report on the working and safety conditions in relation to the new fuel on the 172-metre-long and 32-metre-wide vessel.

»It's a great and exciting place to work, and we're happy that something new is happening and that we're getting some new technology in our hands,« the experienced navigator, who started in Maersk in 1995, says.

With a new system a lot of considerations followed in the beginning, not least in relation to the safety of bunkering, the potential development of toxic fumes, handling in double-walled pipes and the like, but gradually it has 'become everyday life', as Heino Søgaard Nielsen says.

»You slowly learn to work with it, where to keep an eye on what needs to be measured and how to make it run optimally. So at this point I don't think it's that different anymore, except for some teething problems and some extra documentation,« he says.

As a prelude to the stationing at Laura Maersk, he and a number of his colleagues were on a two-week IGF course in Finland to become certified in sailing with methanol. The code is originally related to operation with LNG as a low flashpoint fuel, and on top of that, the crew was specifically taught in methanol procedures.

In addition to the purple bunker zone marking on the deck, those responsible in the engine are very careful to make sure that there is no oxygen in the pipes during the process, which involves purging them with nitrogen, just as there are long checklists associated with the work.

»I'm not worried about sailing with methanol at all. We are sticking to the IGF code for now, and it’s very strict because it’s based on a gas that has completely different properties, and liquid is clearly preferable because there’s no need for all the freezing,« Heino Søgaard Nielsen says.

In fact, Heino Søgaard Nielsen would be more worried about sailing on regular diesel because of the lower auto-ignition temperature of 250 degrees centigrade, whereas that of methanol is 450 degrees.

»When we were on the IGF course and got through the methanol part, people relaxed a bit because we found out that it's not that dangerous at all. Until then, there had been a lot of nervousness, which we also felt when we have been bunkering around the world. But those initial fears have really been put to shame,« he says.

In general, the main engine runs 'surprisingly well' on methanol, Heino Søgaard Nielsen says, pointing out that it lives up to the promises from supplier MAN. Subtracting the small challenges that come with all new builds, the engines have worked flawlessly so far, according to his assessment.