A jack-up rig is not like most other vessels on the seas, and for shipping company ZITON A/S, which has five of its kind, it means a towering focus on safety for both the company's own people and the ships' guests.

On land, people like to say that it is wise to keep both feet firmly planted on the ground. At sea, this can obviously be a more complicated exercise, especially if you work with four legs of up to 80 meters, which sometimes plunge 15 meters into the seabed before finding solid ground underfoot.

This is exactly shipping company ZITON's métier. The Horsens-based company has five jack-up vessels that provide service primarily to offshore wind farms in northern European waters, where the vessels can supply the turbines with new components ranging from gearboxes to entire blades.

UFDS has visited WIND ENERGY, ZITON's largest vessel together with sister ship WIND ENTERPRISE, during a dock stay at the Fayard shipyard in Odense, where the 13-year-old ship has been renovated after purchase.

In the throng between craftsmen, specialists and ZITON's own people on the bridge, we encounter Captain Brian S. Hemmingsen. A 17-year veteran in the shipping company with deployments on all five vessels, he has obtained his fair share of experience of what safety means during proceedings.

»When we are in operation, safety is a huge focus area, both for ourselves and our clients. Things need to be under control, and fortunately we have some digital systems that help us manage everything in the form of work permits, risk assessments, toolbox talks, etc. And it's used every time,« he says.

As an ocean-going vessel, WIND ENERGY does not really resemble some of the other, more traditional cargo and passenger ships UFDS has visited recently. In its basic form, the jack-up is a rectangular box with a length of 100 meters and width of 40 meters, accommodation situated on the foreship, a leg in each corner and a massive crane on the starboard side of the almost 3,000 m2 deck.

WIND ENERGY is thus not built for speed – the transit speed is a modest six knots – and the ship does not have a conventional main propeller, but six 1,600 kW thrusters, powered by diesel generators, distributed on the underside of the hull.

Using them, and supported by an advanced dynamic positioning system and extremely precise GPS measurements, WIND ENERGY can be navigated to a carefully predetermined spot next to the wind turbine to be serviced, after which the over 100-meter-long crane can bring its capacity of 800 tons into play.

»There are safety procedures for everything, i.e. for the entire setup from the moment we approach the wind farm, how we sail in there, navigate and go to a turbine. There are very specific requirements,« Captain Hemmingsen explains.

»When we are in operation, safety is a huge focus area, both for ourselves and our clients. Things need to be under control.«

Brian S. Hemmingsen, Captain, Wind Energy

Serious drill routines

Demands are high when comes to safety during the voyage as well as the work on board, and the shipping company takes this responsibility very seriously, as HSEQ Officer in ZITON Julius Jakobsen emphasizes.

»We make sure to maintain the company's procedures in line with the development of legislation, and if relevant observations are made or incidents occur – this applies here during docking as well as out at sea – we correct them so that our operations can run as efficiently and safely as possible,« he says.

Prior to a job, toolbox meetings are held where everyone involved participates. Here, the course of the operation is clarified, and roles are assigned. Communication is very important on board and great care is taken to ensure that the individual knows exactly what to do, addressing potential doubts up front.

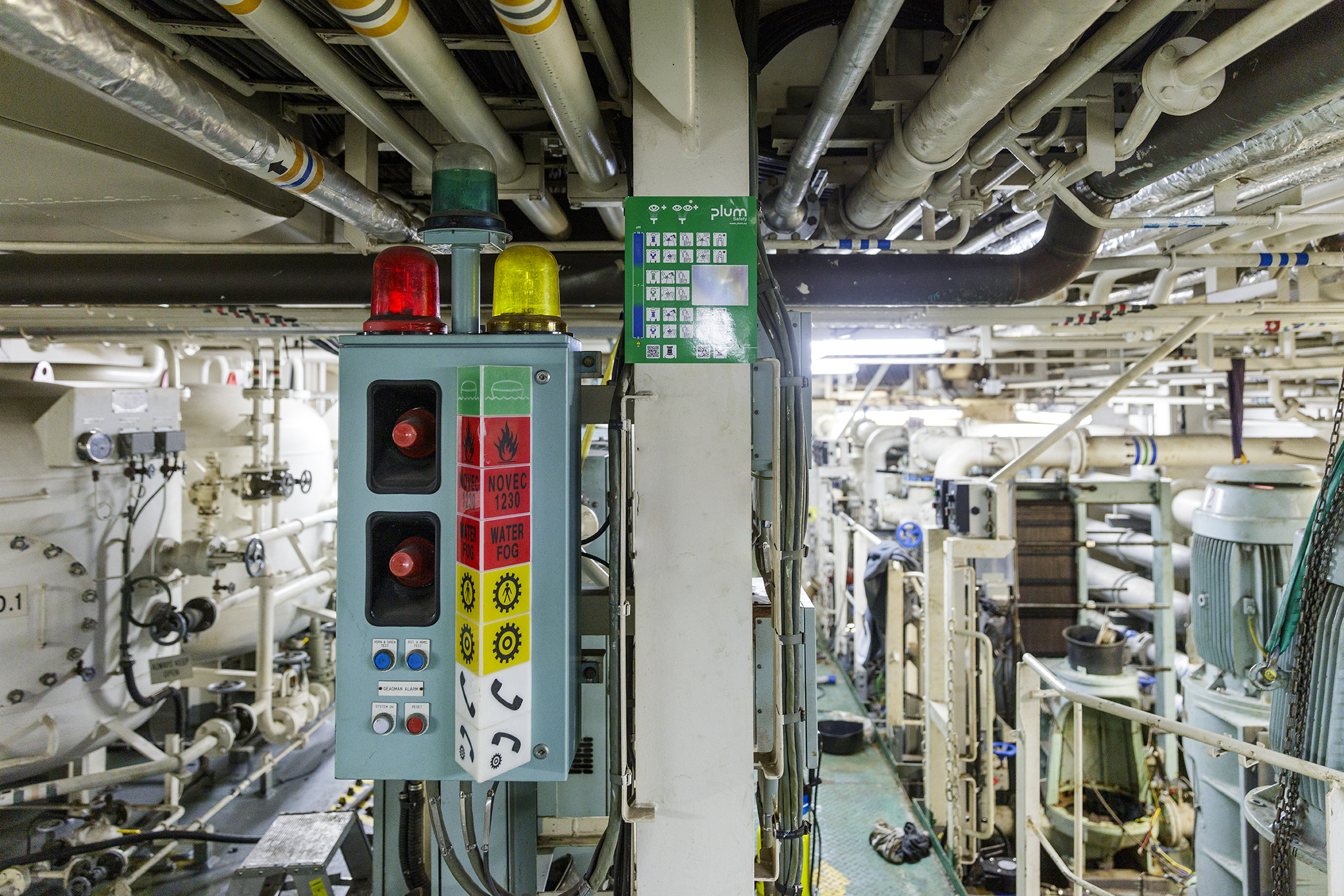

Like other players in the offshore and shipping industry, ZITON also conducts drills at regular intervals in areas such as fire handling, evacuation, helicopter landing, enclosed space, and the like. The exercises are carefully planned and spread out over the year, ensuring all areas are covered

»I have sailed many places other than ZITON, and here we really make something of it. For example, when we have fire drills, we make sure to both test the equipment in practice and talk about the systems on board, so everyone knows what's going on,« Brian S. Hemmingsen says.

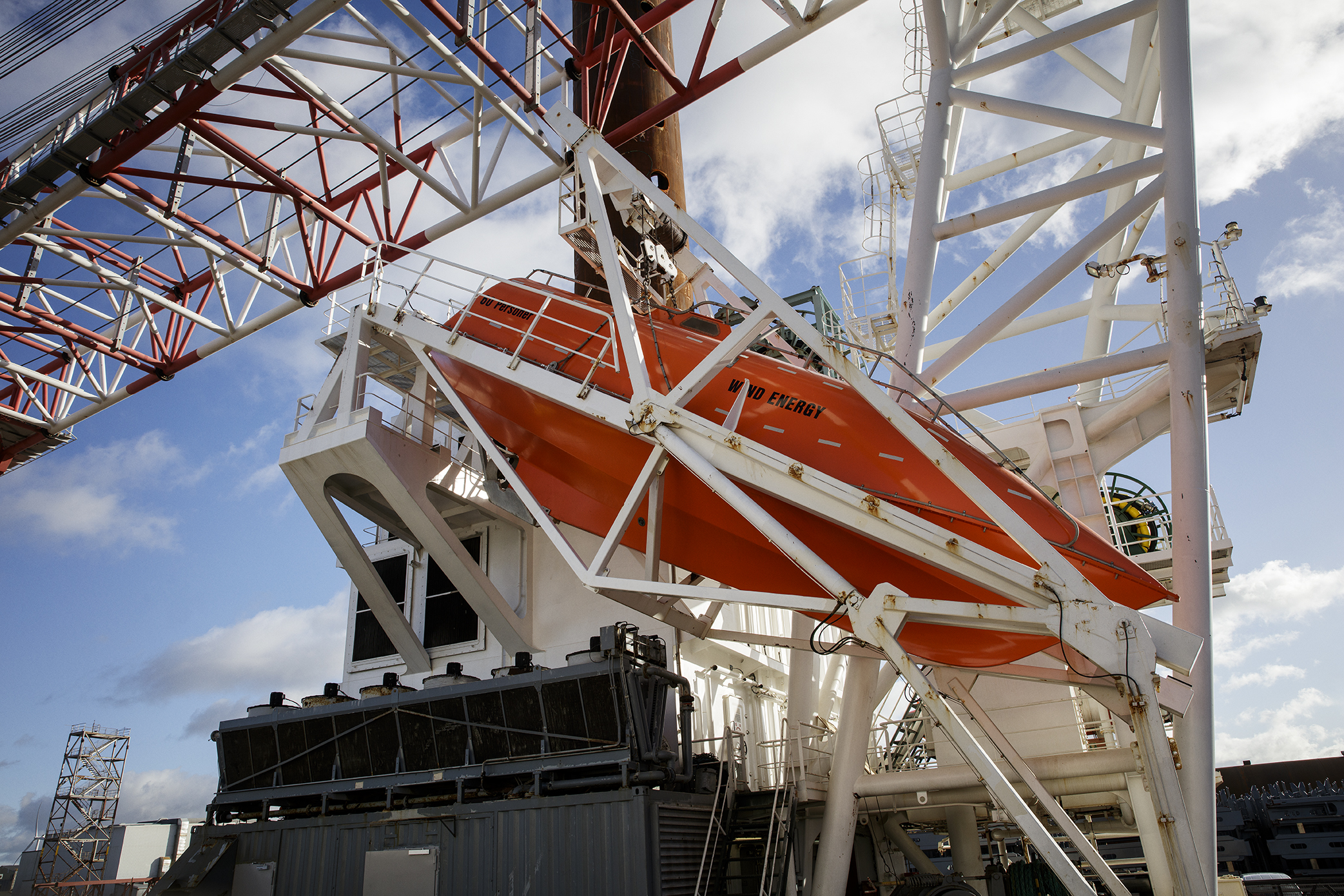

WIND ENERGY has accommodation for 48 people in single berth cabins, and on the large tasks this capacity is fully utilized. Of course, the ship's lifeboats must be able to handle this, and on the day of UFDS' visit, a new lifeboat with room for 80 persons is thus being installed as a supplement to the ones already in place.

On the individual tasks, ZITON's vessels are hired in. To this end, technicians and specialists are accommodated on board, and with both their safety and that of the crew's in mind, the new people are taken into consideration.

»First they get a safety introduction, so they know where to muster in case of an emergency, and then some practical insight follows,« Brian S. Hemmingsen says and continues:

»For instance, they can be introduced to a fire drill. They participate in evacuation exercises, preferably after we have left the port, where we gather everyone at the muster station, and they can see how to get into a survival suit, try to put on a life jacket and see what kind of equipment we use.«

»People need to feel good, and if people feel good, they typically take better care of each other, so it's all connected.«

Julius Jakobsen, HSEQ Officer, ZITON

"If people feel good, they also take better care of each other"

In the HSEQ team, Julius Jakobsen, who joined ZITON as first mate in 2018, and his colleagues have safety and compliance as two main headlines. The goal is that safety is in place while complying with the relevant international standards in the area.

Likewise, if there has been an accident or a near miss experience on a vessel, the department is present to identify what (almost) went wrong, why and what can be learned from it.

»It's never about pointing fingers at people; this is something that is important to us. You can make a mistake, the important thing is that you learn from it," he says.

In order to include the occupants as much as possible in the safety work and the maintenance of a good safety culture, ZITON has a system of digital safety observation cards.

Through these, the occupants can go to the company's online portal and report if they have seen something that in one way or another is not in line with the focus on safety. The observer must also report what was done about the observation or what could be done to prevent future incidents.

»We automatically receive a message from the HSEQ team when a safety observation card is made, and then we can follow up on the cases if necessary,« Julius Jakobsen says.

With both the massive crane, a large open deck, the entire jacking system and a helipad at the top, WIND ENERGY has several areas where a close eye on safety must be kept at all times.

And with the continued pace of the build-out of offshore wind in Northern Europe, the coming years are afloat with prospects of a sizeable workload for ZITON's fleet. All jobs must be carried out with safety at the forefront throughout, as Julius Jakobsen emphasizes.

»This is something we are extremely keen on, both to live up to current requirements, but also because we want to take care of our crews,« he says.

Working conditions for crews are generally a high priority for ZITON, which, among other things, actively adheres to the ILO's Maritime Labour Convention (MLC).

»We are bound by it, and we have good conditions on board,« Julius Jakobsen states and continues:

»We have a great interest in everything playing out, i.e. not “only” safety, but also accommodation, catering, leisure activities and the like. People need to feel good, and if people feel good, they typically take better care of each other, so it's all connected.«