Safety must be both simple and ubiquitous in Esvagt, which has taken several new steps in the area in recent years, according to the shipping company's new head of security. One of the keys is the dialogue with the ships.

Since the Danish Shipowners’ Accident Insurance Association spoke to Esvagt in the autumn of 2022, a lot has happened in the West Jutland-based shipping company, not least on the safety front. For example, the company has a new person responsible for the area in the shape of Head of HSE, Hans Richard Pedersen, whom we have visited on one of the shipping company's vessels, the Esvagt Faraday.

However, Hans Richard Pedersen is far from new to Esvagt. In fact, he joined as a seafarer back in May 1998 and spent almost three years at sea before going ashore. Since then, he has been through several different positions, before becoming head of security in February 2023.

»When I started here, we numbered 9-10 ships and about 100 employees offshore, plus 10-12 people in the office. But a development was underway, the board wanted to have an actual personnel department, and then I was pointed out. So, I was given responsibility for our offshore employees and had it for 17 years, including a year as HR partner towards the end,« he explains.

By the end of 2017, however, Hans Richard Pedersen needed a change of scenery and became Fleet Manager Operations – including for Faraday – while taking a Graduate Diploma in Organization and Management. Five years in that role was an excellent approach to taking on the role as Head of HSE.

»HSE is not a new area for me as such; I have always worked with safety, but now I suddenly became the head of the effort. And only 12 days in, we had a serious incident where a marine engineer was very badly burned by some boiling steam. So, it was a tough start, and looking back it’s still one of the three worst accidents I can remember through all my years here,« he says.

As one of his first moves in the new role, Hans Richard Pedersen hired another former seafarer – a navigator like himself – for his team based on the consideration that it is important to have people on the team who know what it means to be on board a ship. Later they were joined by a marine engineer with many years at sea behind him.

»I thought getting a different angle on the technical side was really healthy. So now we are a department of six people; three in the office and three HSE officers who travel around visiting the ships. One of them actually divides his time equally between office and offshore,« he says.

Wants to simplify procedures

The overall focus is that working with security should be easy. With this in mind, Esvagt has made many changes to its approach, including obtaining an ISO 45001 certification in occupational health and safety management last year. But you don't make changes for the sake of changes, Hans Richard Pedersen states.

»We do it because we listen to what is happening on the ships. And we are embracing it in order to make the work of the people easier. I have a big dream of simplifying our procedures; They are often written in an 'academic' language, but the expectation is that all employees should be able to sit down and read them. And that is not the case today,« he says.

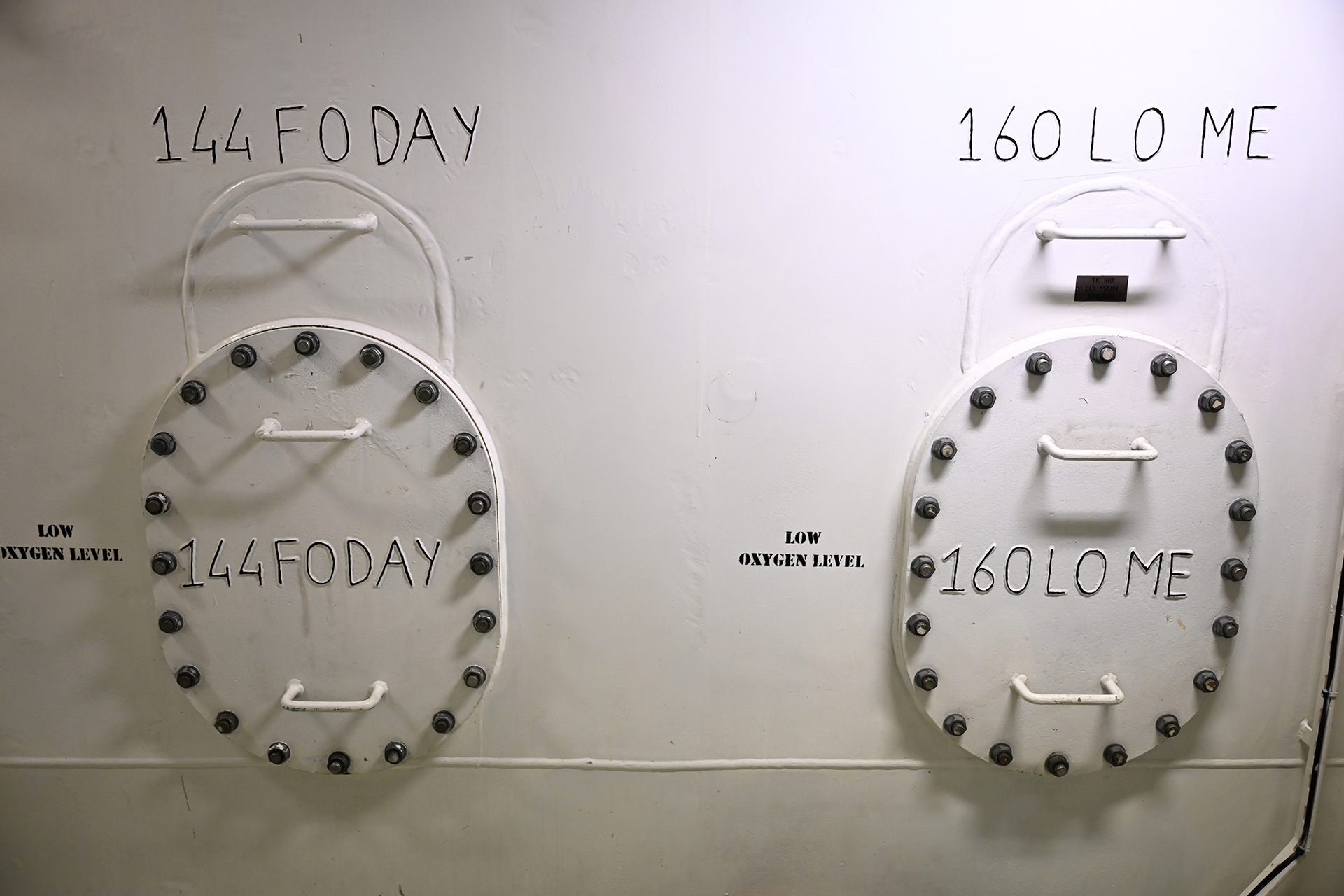

This type of equipment must be made more accessible to all professional groups at sea, Hans Richard Pedersen adds, having sailed himself with skilled deckhands and other professionals who were also dyslexic and therefore challenged on things such as procedures.

In addition to the HSE work being easy, it must also make sense for people on the ships, he points out. Therefore, the shipping company also makes a lot of effort to involve the crews from some of the ships and also make sure that they have the right skills for the job.

For example, some of the people from Esvagt Faraday have recently been deeply involved in chemical segregation, allowing them to better ensure that various chemicals on board are stored correctly.

»In principle, it could be a matter of time before we had an accident, so this year we have chosen that all Esvagt vessels must focus on their chemical segregation. Because there was room for improvement, and that is a dormant factor in my view, and we learned a lot in connection with the introduction of ISO 45001, which could benefit other of our ships,« Hans Richard Pedersen says.

Thus, it is also about being proactive and foresighted, he adds. To this end, he highlights Esvagt's reporting culture, and especially the two lower layers of the classic safety pyramid, which are partly near misses and partly – at the very bottom – observations that people can report on so-called learning cards.

»There is a huge learning potential in all the things that don’t happen. We have almost 9,000 reports a year, so there is great value in the learning cards we receive, and they are a fantastic tool for the ship's on board management to get a read on what is actually happening on the vessel,« Hans Richard Pedersen explains.

Have to deal with different perceptions

An important point for Hans Richard Pedersen in connection with new safety initiatives is that he and his colleagues set the level of ambition at the right place. Esvagt currently has over 1,300 employees and 43 vessels, plus a few more on the way, and it takes time to implement new initiatives across the organization.

»It requires us to be sharp at explaining the things we want to happen, and also that we are good at following up on the suggestions we make. There are clearly areas that we in the HSE team could have done better, and we must learn from that. We need to involve and talk to the people on the ships, and they need to know that they can always come to us in the team with questions or suggestions for improvements. Our door is always open,« he stresses.

He also emphasizes that as a crew member, you should not hold back if you feel that you have seen something that did not look as it should – even if nothing happened in the given situation.

»You shouldn't hesitate to talk about the experience you've had. And then it may well be that there will be disagreements about some issues, but that does not change the fact that there is a person who has had a different perception of an incident, and we have to deal with that,« Hans Richard Pedersen says.

For the HSE department, it is also about what he calls 'demonstrable care', i.e. that they want to show that they take care of their employees and that they do everything in their power to avoid accidents.

»The worst thing I can imagine is when a colleague comes home to his or her family with a work injury. Or that he or she doesn't come home at all. It's a terrible thought. And all injuries are equally important, and all injuries must be avoided. But we're actually really good at it,« he says.

Along those lines, Hans Richard Pedersen points to the key in not "only" gathering insights when something goes wrong, but that you harvest experience from all the – many more – times when things are going well.

»It's a bit like a good marriage counselor only learning from all the divorces. But you also have to talk to the people who’ve been happily married for 30 years. In our case, it is all the incidents down at the bottom of the pyramid, where there is a lot of good knowledge to be gained, plus the many thousands of successful operations and tasks we solve daily,« he says.

At the proactive and sustainable level

In January 2024, Esvagt completed an internal survey focusing on where the organization is on what Hans Richard Pedersen calls the 'safety culture ladder'. The ladder has five rungs, starting with an unhealthy environment with many incidents and a tendency to point fingers at people at the bottom.

The next step is the reactive one, where things are taken seriously and good procedures are in place, but reacting to accidents proves difficult. The third step is the descriptive one, where all companies – according to Hans Richard Pedersen – would like to be today. There are also a lot of procedures, statistics and the like, and people are active, but accidents still occur.

A step further up, we find the proactive level, where the organization is at the forefront of things, people get involved and take ownership. And finally, the sustainable step at the top, where safety is the business itself. This is where Esvagt strives to be, Hans Richard Pedersen emphasizes.

The shipping company gets insights into this from a questionnaire consisting of 11 sections with a total of 28 questions answered by the individual crew members. On the vast majority of parameters, the answers place Esvagt on the top two levels, i.e. the proactive and the sustainable level.

»Normally, the approach is to focus on the places where the assessment is down to the two lowest levels, but we have received very few answers in those categories. Instead, we have identified five areas in the middle stage, which include involving employees and how we get safety worked into our daily tasks and operations,« he explains.

Esvagt has also held officers' seminars to involve the crews. The participants have been the ships' top-4 in the form of captains, 1. officers, chief engineers and 1. engineers, sitting down to talk about how to promote on board safety actions.

»They then had to describe not only some initiatives, but also how to anchor them in the organization. We have grouped all of this input under four headings – employee involvement in safety, feedback on work performance, ideas for safety improvements, and Success vs. Failure,« Hans Richard Pedersen says.

Along with the cultural survey, the conclusions have been summed up in the ESVAGT Action Plan Offshore, which is now available in digital form on board all the ships. The digital approach is underlined by the fact that the shipping company is in the process of rolling out tablets to all the vessels, allowing crem members to work directly in their own template on site.

Internal and external control

The philosophy of making safety work easier in the Esvagt includes simplifying the way the crew must register toolbox meetings (TBTs). Previous efforts included three types of TBTs – formal, informal and last minute – but now the focus has narrowed down to one only solely requiring the crew to register that a meeting was summoned, what the headline was and who attended.

»People should talk about safety rather than spending time filling out forms about it. Similarly, they can now also take a work permit with them on the tablet and check the workplace according to what has been agreed in the permit. And they can use it for checklists on the bridge and a lot of other things, so again: It's about making safety work easier,« Hans Richard Pedersen says.

The individual vessels are also called upon to appoint a safety supervisor responsible for the agreed issues concerning safety barriers, and also to continuously monitor a task, as the conditions can change during the execution.

When it comes to safety leadership, Hans Richard Pedersen advocates for a bottom-up approach, allowing safety ideas to germinate among employees and move upwards when a good idea materializes.

»We have laid the groundwork, but if you as a captain or chief engineer want your people to be headed in a certain direction, then you have to set some goals. And knows his own crew better than a captain or chief engineer, so this is where autonomy comes in and lets them set their own goals within the framework we have defined,« he explains.

As an example, Hans Richard Pedersen shows how the crew of the Esvagt Faraday has developed a goal of 'Employee involvement in safety' (cf. fact box), which means that the captains involve the people and create a culture where every topic can be tabled, and no issue is too small.

»It's also very much about the psychological working environment and that people feel safe talking about the things they experience in relation to safety and the on board working environment in general. And this also includes our guests on board the vessels, where we take technicians, who are usually not seafarers, out on our wind ships,« he says.

»Last year, we ran a campaign about severe weather damage, from which we learned a lot that we can utilize now, because even though we don't have direct control over, for example, the on board warehouse the customer uses, we still have to make sure that things are properly secured and make them aware of it,« he adds.

Esvagt continuously monitors the development of the various initiatives and can, for example, see that the safety supervisor has been implemented on virtually all the ships, just as they try to follow up on whether it actually works in reality.

In addition to internal control, Esvagt itself is audited on its work with International Safety Management (ISM) by Bureau Veritas, which is presented with plans and initiatives, as well as visiting the ships and looking at whether the initiatives are making a difference in everyday life.

»I'm a big supporter of people thinking for themselves. The best tool you have to work safely is the one you have between your ears. That said, you shouldn't add too much load onto the captains, so that's why we have the overall guidelines in place and a level of autonomy underneath where they can decide for themselves,« Hans Richard Pedersen says.

Safety management - ESVAGT Action Plan Offshore

The captain and senior officers must set goals for the ship's crew, support the safety culture, and act as role models. When referring to senior officers, this also includes 1. officer, chief engineer and 1. engineer.

- 1. Employee involvement in safety:

The captain and senior officers must inspire and encourage the crew to understand that safety initiatives do not necessarily have to come from the officers only. All employees are encouraged to independently identify and resolve safety issues.

In addition, any member of a team or department can take the initiative to address security issues in their own or other teams. The goal is to facilitate the active participation of all crew members in identifying and resolving safety issues and taking the necessary time to carry out the work safely.

- 1. Feedback on work performance:

The captain and senior officers, together with the crew members, must actively promote a working environment where everyone consistently helps each other and provides valuable and constructive feedback regardless of rank. This feedback should be aimed at improving security performance.

A psychologically safe work environment is essential to facilitate this, by promoting trust, effective communication, and continuous learning. Leading indicators can be recorded as an observation, which enables us to learn from these events and share feedback effectively with the crews.

- 1. Ideas for safety improvements:

The captain and senior officers must actively encourage and promote suggestions for improvement from crew members. Suggestions for improvements received should be appreciated, considered and followed up.

- 1. Success vs. Failure:

To encourage a proactive culture of safety, it is important to analyze both the positive and negative outcomes of work and operations with equal thoroughness. Both positive and negative work performance must be analyzed together with the crew. Successes must be consistently rewarded, while failures must be embraced and seen as an opportunity for improvement and learning.