With a cargo hold full of petrol and other flammable liquids, safety must be top notch, and the crew at chemical tanker Ternholm therefore does their best to ensure exactly that on a daily basis. Checklists, risk assessments and strict procedures are therefore commonplace for the crew.

Access through a manned gate featuring its own control tower, a bit along Smöroljegatan, then Bentylgatan, down to berth 511. No pictures from the dock, phones in flight mode. Yes, Skarvikshamnen in Gothenburg is different from the passenger and freight terminals in Ijmuiden, Elsinore and Nynäshamn.

UFDS is visiting the big city in Västra Götaland County, where shipping company Terntank has extended an invitation to board the motor tanker Ternholm, and as the location amply suggests, this time there are no trucks, busses, or families with children to take into account.

However, this does not mean that safety measures are dialed down, quite the contrary actually, because when the cargo is made up of chemicals and petroleum products of the highly flammable kind, strict protocols are to be observed and absolutely no room is left for unnecessary risks.

Such is the explanation by the ship's captain for the past almost 15 years, native Swede Kristian Jönsson, as UFDS meets him on the bridge together with compatriot Elias Möller, who is chief officer on the vessel.

»Safety is everything on board a tanker. We have checklists, risk assessments, procedures, manuals and so on for just about everything. Every time we perform a task, we do a risk assessment first, so we constantly think about safety,« the captain said.

He goes saying how all equipment on the ship is gasproof, i.e. secured to be near the flammable liquids, and that there are strict requirements for the crew's equipment, such as safety goggles – a kind of ski masks – when working on deck.

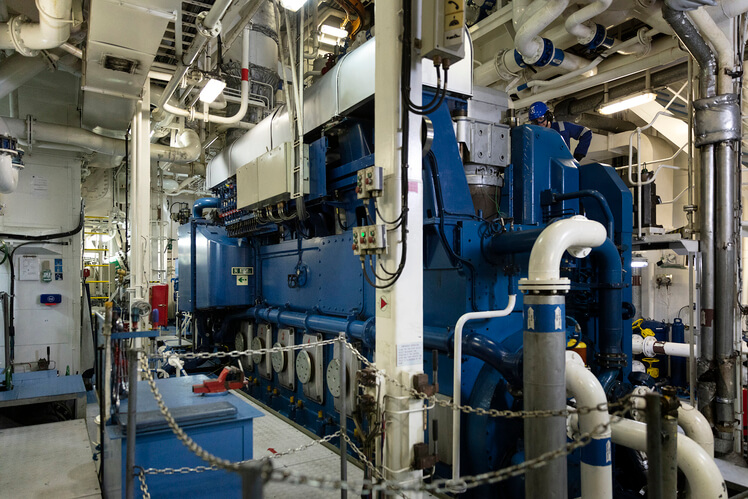

UFDS has witnessed all this firsthand through an extensive tour of the ship which offered both a look in the engine, workshops, control rooms and the so-called pipe trunk, where pipelines run below deck for most of the ship's length before the tour concluded on the bridge.

Other types of risks than ferries

Ternholm was built to order from Terntank at a shipyard in Shanghai in 2005 and has since then sailed primarily in the Baltic Sea, to Fredericia and on to Sweden and Norway, as well as around England and in the North Sea region. The central bulk liquid tank on the 141-metre-long and 21-metre-wide vessel holds almost 16,000 cubic metres.

The crew is 12 men, often supplemented by a cadet or two in training. Upon arrival in Gothenburg, the ship had been about three days en route from Finland, and where afterwards due to head back to Hamina in the southeastern part of the country, close to the Russian border.

To make ends meet as far as the sailing schedules go, the crew is on board for five weeks at a time and then at home for five weeks, which according to Kristian Jönsson works excellently.

Ternholm thus differs a great deal from the combined passenger and freight ferries that UFDS has previously visited in connection with this series of articles. This is also reflected in the types of risks that are present on board.

»When we haul petrol products, we always keep safety in mind, but that's just part of the job. If we have to change a lamp in a mast, then we need a permit, if we have to do something on the deck, there must be a permit, and that's how it it is all the way through,« Kristian Jönsson says.

As part of their deployment, the crew conducts computer-based training, which must be continuously renewed, combined with courses in, among other things, basic safety, fire handling and correct operation of relevant equipment.

»In addition, we have drills once a month where we rotate between different scenarios, so it's not the same every time. But it's always fire drills, man overboard and lowering the lifeboat every month, and then the other things change. Enclosed space is often on the program,« the captain says.

Should an accident nevertheless occur, the head office on Vestre Strandvej in Skagen, where Ternholm is registered, is always within reach, and additional ground crew in both North Jutland and the liner’s Swedish office on Donsö in the archipelago south of Gothenburg are on hand to handle other safety related questions.

Target of 24 near miss reports per year

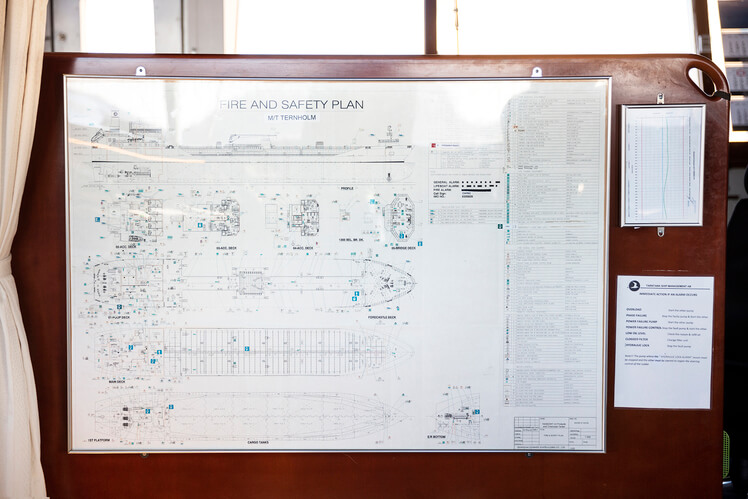

Both in the conversation with Kristian Jönsson and through the tour of Ternholm, it quickly becomes clear that fire safety is – naturally enough – among the very top priorities on the vessel. Thus, the ship has two fire stations, in addition to 50-60 powder and foam extinguishers around the aisles, the engine and so on.

The sprawling sprinkler system is tested once a week, and a gas measurement system monitors air quality through sensors that measure oxygen and hydrocarbons. Everything is of course connected to alarms that howl if something is off.

As a curious coincidence, on the same day as UFDS is on board, Ternholm is also hosting the annual visit of an inspector from C Survey, going through fire equipment, life saving appliances and the like. To this end oxygen cylinders and masks, safety harnesses and much more are scattered across the door in the crew's TV room. The inspector went along the journey to Finland and back again as to cover all the bases.

»We have this type of inspection once a year, and in addition, various oil companies also visit every six months. So it's safety 365 days a year, otherwise we couldn't sail anywhere,« Captain Jönsson says.

Safety is of course also in focus when the ship is in port and the expensive droplets are pumped to and from the cargo hold. Kristian Jönsson shows UFDS 10-page document stacked with boxes to be ticked off in connection with unloading and loading the flammable liquids, and goes on to explain how people from the docks come on board when the ship has berthed to assess the situation.

Like Stena Line, Terntank also boasts an experienced staff of sailors who have been with the shipping company for a long time, although they to a greater extent rotate between the different, but still relatively similar ships in the company's fleet.

»It's a great company to are part of, with a really good eye for safety, so it's very rare that we experience something serious, otherwise it's small stuff like the chef cutting his finger. And if something bigger should happen, we fill out a marine injury report and file it,« says Jönsson.

As an example, he cites an incident when he himself fell in his cabin during bad weather a few years ago and injured his arm, after which a report was sent. The captain rates the subsequent process of checks and follow-ups as "very good".

In addition to the damage reports, the crew also prepare the occasional near miss report, with a target of 24 per year and preferably at least one from each position on board. It is often during inspection rounds that smaller issues are revealed, or if one of the crew members spots something during the days onboard.

»It's very rare that anything actually happens, because everyone checks everything, and checks everything, and checks everything again. But when we get north and it's cold, ice can form on the deck, so it becomes slippery, and this can lead to a near miss,« Kristian Jönsson says.

Cash prizes for good safety ideas

As the overall reason for the good safety culture and the very few incidents on the ships in general, Kristian Jönsson points to the close contact with Terntank's offices, both in Skagen and on Donsö. When something happens on rare occasions, they are effective in sending out a safety bulletin notifying all the vessels.

»This allows for all crew members to become aware of whether we may have the same risk here on board and can avoid it. So, we share that knowledge along with best practice so we can learn from each other,« Captain Jönsson says.

In addition, all ships calling at Swedish ports can send good safety-related ideas that can benefit all sailors to the Swedish Maritime Administration in Stockholm. From here, the best proposals are continuously awarded, which the crew at Ternholm have tried themselves.

»We have been awarded for several proposals. For example, we have some fairly large cargo hoses on board, three six-inch hoses that are 18 meters long, and an eight-inch hose. They are located down in the pipe trunk, and from there it is quite a heavy task to get them up on deck through a hatch,« Kristian Jönsson explains.

»One of the sailors then constructed two wagons with wheels that can pull the hoses up without the crew having to stand and drag bent over in a working position that is quite bad for the back. He got a cash prize for that,« the captain continues.

Such ideas come up regularly, he says, pointing out the 20-metre-long loading crane on the deck. At the far end of it is a wire block that needs lubrication from time to time, which used to be a particularly risky task, until a sailor recently suggested leading a small pipeline all the way to the crane tip, so that the bearing can be lubricated from a distance at a safe position by the crane's base.

In this way, the crew constantly make sure to be updated on both equipment, knowledge, and new initiatives – also about, for example, navigation and safe maneuvering in the ports – so that the risk of accidents can be kept to a minimum.

'Take it easy'

One of the members of Ternholm's crew with concrete safety measures as part of his daily agenda is 1. officer Elias Möller, whom UFDS meets on the bridge, occupying his regular spot behind the computers next to Captain Jönsson.

From here he monitors a wide range of the ship's systems, in addition to its position, speed (12.7 knots is the optimal cruising speed), the condition of the cargo and much more. For him, safety is first and foremost a matter of thinking when moving around the ship or performing tasks.

»The key must be to not put yourself in unwise situations, but rather taking it easy instead. No one thanks you for running unnecessary risks, even though you might be able to do something a bit faster. So, safety is very important, and I feel best here when I know that everything works and has been thoroughly tested,« he says.

Not taking chances or rushing with a task is also about taking the time to familiarize yourself with a manual or a guide, and indeed not hesitating to ask for help if in doubt about an issue, he points out.

»It’s very important to have good cooperation between all the staff on board. You should not take on all the responsibility alone if something breaks down, because that does happen. You have to have a good culture where you don't push the boundaries,« says Elias Möller, who has spent seven years in Terntank on a number of different vessels.

»These sister ships are pretty similar, but of course there are also differences in how you approach some procedures. So, if someone comes on board from another boat where you perhaps do something in a smarter or safer way, you listen and try to transfer that approach,« he says.

Human life is always the top priority

As a prelude to the meeting with the officers on the bridge, UFDS enjoys, as mentioned, a walk through the control room and the engine, where safety is of course also a recurring factor. Here, chief engineer Zdzislaw Makar bids welcome after 3rd engineer Grant Gacanyan has hosted the tour around the engine compartment itself.

The propulsion system at Ternholm, where the main engine is a four-stroke Wärtsilä 6L46C producing 6,300 kW at 500 rpm, does not differ much from other vessels in the same weight class, but with the sensitive cargo in mind, the crew likes to go one step extra to do things by the book.

»We always start the day with a meeting, which is important to have an overview of what is going to happen that day, who is going to do what and how. In this way, we can talk our way through how to do it – perhaps with support from the office – if, for example, we need to change a critical component,« he says.

As Captain Kristian Jönsson has also mentioned, a task always begins with a risk assessment and in some cases a permit, ensuring that safety measures is in place. If not, a revisit to the assessment, and possibly improving the conditions, is called for.

It is tasks such as the classic enclosed space, welding or grinding (with a risk of sparks) that require permits before they can be performed, just as the bridge must be notified in advance. Similarly, a series of preventive checks are also carried out while the ship is in port, while other, minor maintenance tasks can be carried out at sea.

Similar to the extensive checklists the captain was able to present in connection with cargo handling, Zdzislaw Makar and his team have their own lists to consider when Ternholm is going in and out of various ports, so that everything is ready before the engines are started or shut down.

In addition, the engine crew is a key part of the monthly fire drills, helping to ensure that equipment for, for example, smoke diving is in order. And should a fire in the engine room develop to critical levels, Zdzislaw Makar oversees managing the effort in relation to extinguishing, sprinklers, CO2 system and so on.

»Depending on how a fire has arisen and develops, we may have to turn the ship around, shut down parts of the engine or whatever it may be before we can move in with the fire hoses and get the fire under control. Because if we cannot control the situation, we have to evacuate people. Human life is always the most important thing,« he said.

Finally, he is also partly responsible for the frequent exercises with the two lifeboats on board. Partly the fast rescue boat, which is used for man overboard situations, and partly the larger lifeboat, which is suspended and ready for a quick departure from the stern of the ship.

The former is required by the authorities to be lowered (but not necessarily launched) every three months, but Ternholm has chosen to do this every month, weather conditions permitting, which can be a challenge in winter.

With that, UFDS leaves Ternholm and berth 511 in Skarvikshamnen, while Captain Jönsson and crew prepare for another trip up through the Baltic Sea. Always with top level security.