Ammonia is one of the climate-friendly fuels of the future, but the use of the toxic product comes with some new safety risks for the industry to address. Engine manufacturer Everllence is already doing this – and it's not really that difficult.

The green transition of the shipping sector is in full swing, so that the industry on a global level – hopefully – can achieve the IMO's goal of net-zero emissions from international shipping around 2050. The task is large, and several of the members of the Danish Shipowners’ Accident Insurance Association are already well underway with various initiatives.

Among the most well-known examples is probably A.P. Moller – Maersk's focus on fleet decarbonization, where one of the primary measures is methanol as a fuel. Bio- and e-methanol can reduce greenhouse gas emissions by at least 65 percent compared to conventional fossil fuels, according to the shipping company.

The use of methanol on vessels such as Laura Maersk and her larger siblings is practically directly dependent on dual fuel engines that can swallow the new fuels side by side with bunker diesel, which will remain necessary for a number of years to come while the production of green methanol gets up to speed.

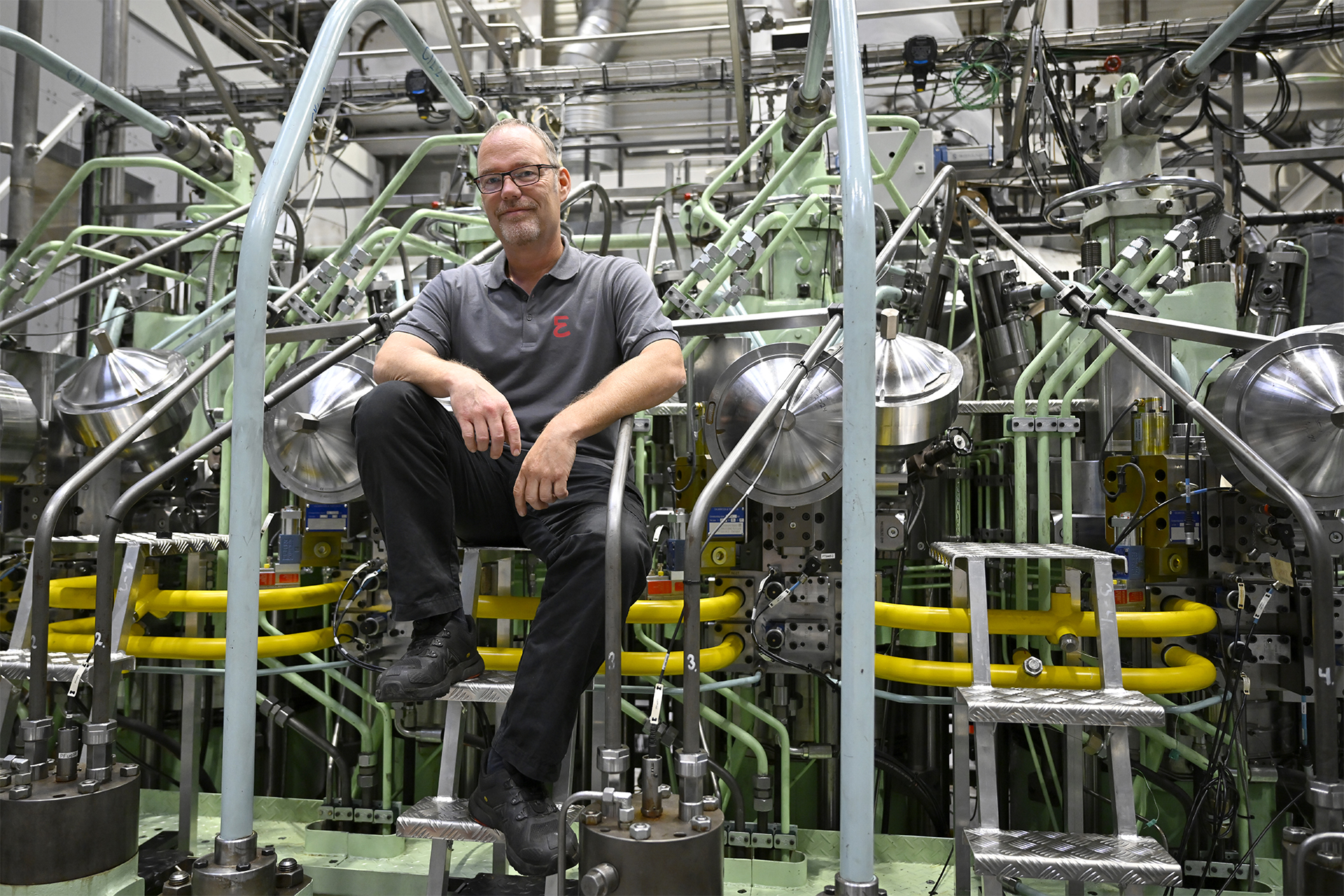

The engines are supplied by among others MAN Energy Solutions, which has recently changed its name to Everllence. UFDS has visited the company's Danish head office and test center in Copenhagen to have a chat with Senior Superintendent Lars Bay about the perspectives.

»We’ve been running with ammonia on our test engine for almost two years, first on one cylinder, now we are on all four, and it’s actually quite simple. Our design philosophy is that as a technician, you should be able to work with the engine and disassemble things without being exposed to ammonia to any significant degree,« he says.

'Significant degree' covers the fact that you will probably be able to sense it – the human nose captures ammonia already around 5 ppm – but is far from something that requires respiratory protection or the like, and it is only in connection with maintenance that you will be able to smell it, Lars Bay emphasizes.

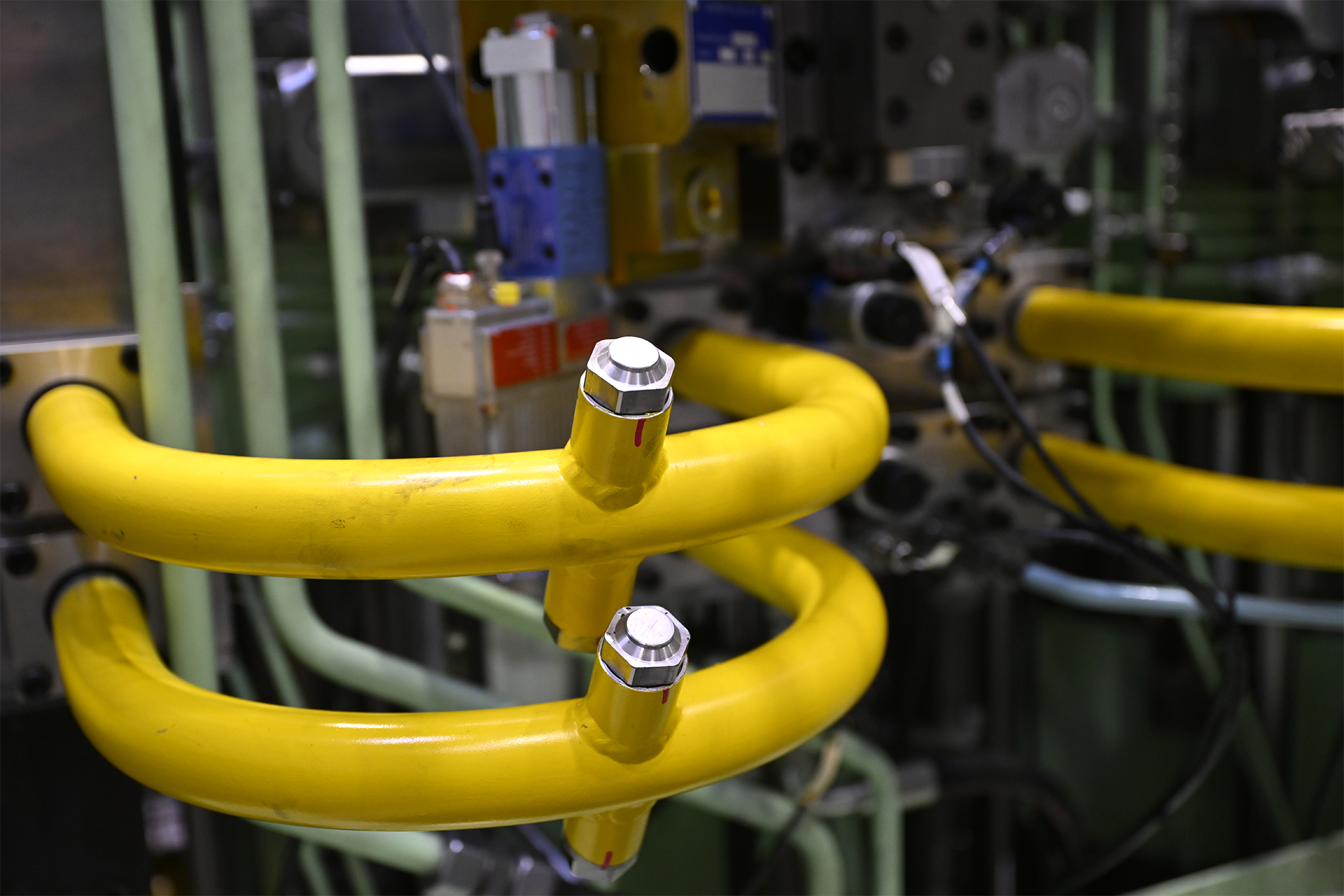

On all of the company's second-fuel engines – that in addition to ammonia can also use, for example, methanol, methane or LPG (liquefied gas) – Everllence uses double walled pipes, where the fuel itself moves in the inner tube, which is then enclosed by an air-ventilated outer tube with negative pressure.

»If a leak occurs in the inner pipe, where you can have the ammonia running at 80 bar, as we have here, it will be detected in the outer pipe, just as the outer pipe will be pressure verified at every start-up. And if the negative pressure disappears in the outer pipe, the system closes automatically,« Lars Bay explains.

Water curtain as an obvious solution

There is a strong focus on safety when starting up and operating the ammonia-powered engine, and the same is true when it comes to carrying out maintenance. Prior to the task, the double walled pipe can be “flushed" (purged) with nitrogen, allowing for a safe disassemble the engine.

»The main idea is that if you do things properly, read the instructions and keep your head in the game, there are no more risks associated with an ammonia engine than there are with one running on conventional diesel. But of course, in general, you have to know what you're doing,« Lars Bay says.

This is especially true in connection with bunkering of ammonia, which Everllence itself often does. To this end, the main ingredient in the safety measures is simply water, which in the event of a leak can quickly and efficiently dilute the ammonia into a thin spirit, which can then be collected in a tank before disposal.

»Out on the ships, you’re naturally surrounded by water all the time, so I could imagine that you can make a water curtain around your bunker station, which is also what we’ve done here, but it's out of our hands. On the open sea, you can also partially evaporate some of it, we just can't do that here, where we are surrounded by the city,« Lars Bay points out.

As a fuel, ammonia has the advantage that it burns much cleaner – not least without CO2 – than diesel. However, a small proportion of diesel, about five percent, is needed to ignite the ammonia, which is otherwise a refrigerant, but according to Lars Bay, burns surprisingly well.

»The new risk that comes with it is toxicity. That's also why we're going belts and braces here with double walled pipes, nitrogen purging and so on. And therefore, we don't have any extra requirements for PPE (personal protective equipment, ed.) other than putting on some safety glasses in case of oil splashes, but there’s no need for respiratory protection and that sort of thing,« he says.

Risks are minimized to the letter

In connection with the company's own bunker station, Everllence has established a building, open at one end, where the tanker reverses over some simple spill trays in the floor. Should a leak occur, it will be caught by sensors that close the doors at the opposite end of the room and start the water system.

»It's really just a sprinkler system, pretty simple. But it is enough to make sure that we can catch the vapors from a spill, so that you can actually stand right in front of the building here without being able to smell anything. And I don’t mean to undersell it, because ammonia is toxic, but in this way it is not very difficult to deal with,« says Lars Bay.

At the bunkering station itself, i.e. where the ammonia is to be pumped from the tanker to Everllence's system, there is a requirement for full PPE. Everllence receives the ammonia liquified under pressure, and the fuel lines are fitted with couplings preventing the liquid from flowing until they are sealed.

»We have tried to make it as fail-safe as possible, so that the risks that exist are minimized according to the letter. For example, the couplings have a snap away function, so even if the hose is pulled off by accident, the valve closes immediately,« Lars Bay explains and continues:

»We have gone all-in on security and tried to consider all possible scenarios, almost no matter how unlikely, except perhaps deliberate sabotage. The natural reaction would be to step away, because it frankly tears at the nose, but you do need some procedures for it. And there are standards for how large concentrations you can be exposed to for how long, so we lean on those as well.«